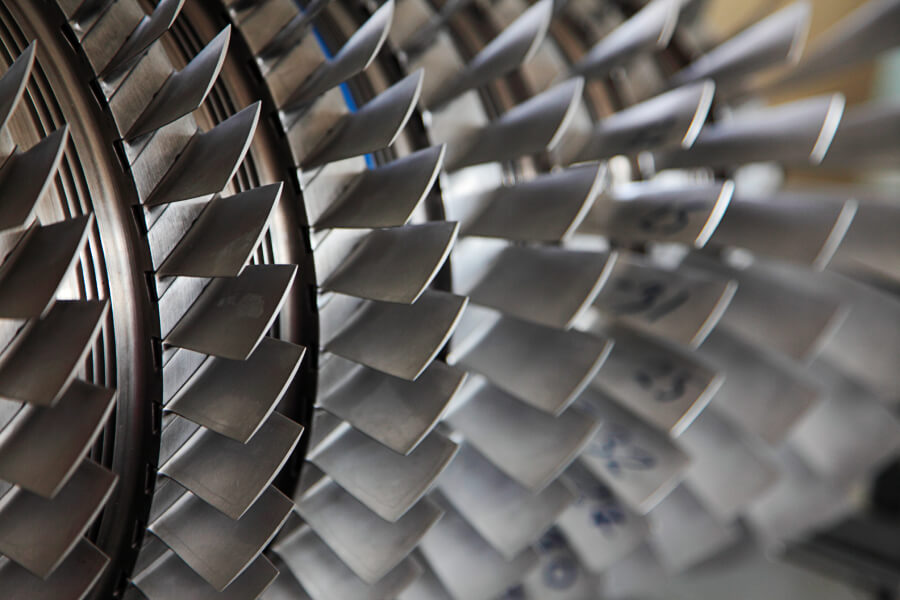

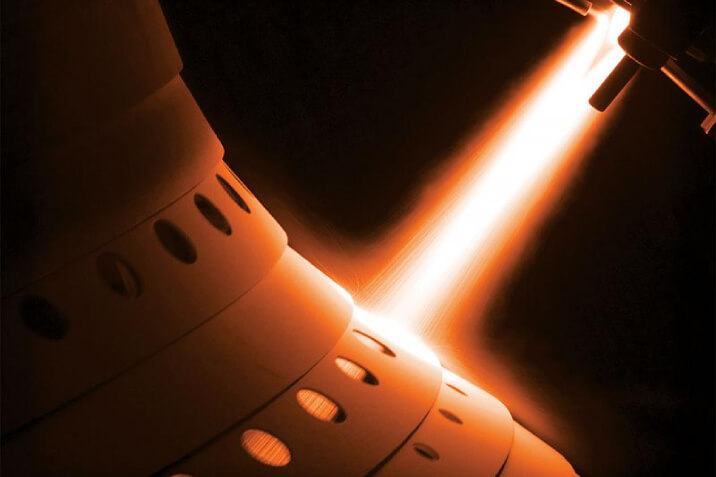

- Precision Machining:Aircraft engines require high-precision components to ensure optimal performance and safety. Machining shops use advanced CNC (Computer Numerical Control) machines to manufacture engine parts with tight tolerances.

- Materials:Aircraft engine components are often made from advanced materials such as titanium, nickel alloys, and composites. Machining shops must be equipped to work with these materials to meet the stringent requirements of aviation standards.

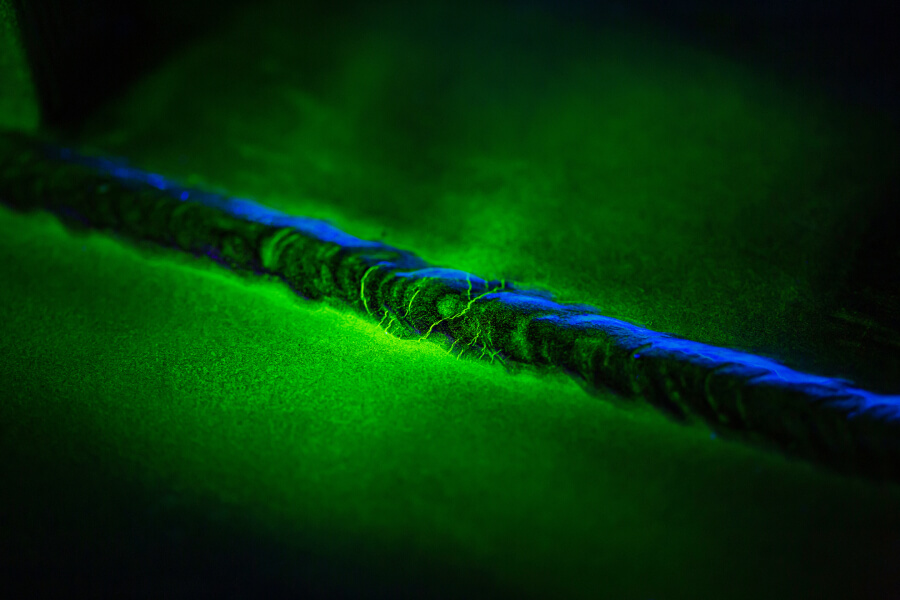

- Quality Control:Strict quality control measures are essential in aircraft engine machining. Components must undergo rigorous inspections and testing to ensure they meet industry standards and specifications. This includes dimensional checks, material testing, and non-destructive testing (NDT) methods.

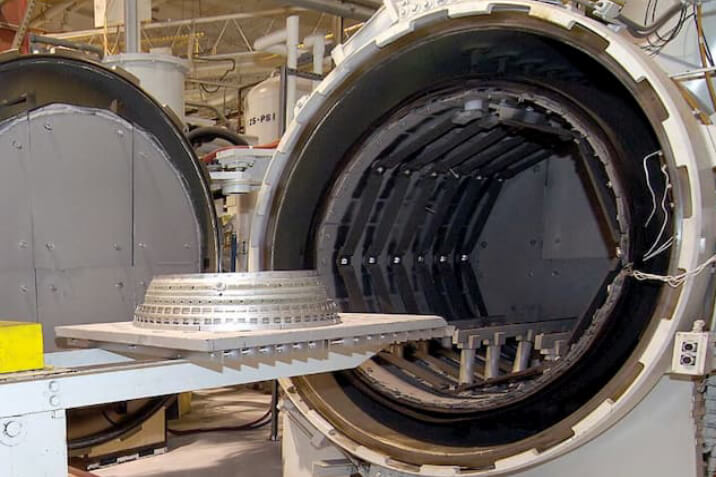

- Repair and Overhaul:In addition to manufacturing new components, machining shops also play a critical role in the repair and overhaul of aircraft engines. This involves refurbishing worn or damaged parts to extend the lifespan of the engine.

- Certifications and Compliance:Aircraft engine machining shops must adhere to aviation regulations and obtain relevant certifications. Compliance with standards such as ISO 9001 and AS9100 is essential to ensure the quality and safety of the produced components.

- Advanced Technologies:Keeping up with technological advancements is crucial in the aviation industry. Machining shops may use advanced technologies such as additive manufacturing (3D printing) for certain components, as well as digital tools for design and simulation.

- Collaboration with OEMs:Machining shops often collaborate with original equipment manufacturers (OEMs) or engine manufacturers to ensure that the produced components meet the required specifications and standards.

- Skilled Workforce:The workforce in an aircraft engine machining shop includes highly skilled machinists, engineers, and technicians with expertise in aerospace manufacturing and machining.