In the context of aerospace, an aerospace grinder refers to a specialized type of grinding machine used for precision grinding and finishing of components and parts used in aircraft and aerospace applications. These grinders are designed to meet the high standards and strict tolerances required in the aerospace industry. Here are some key aspects associated with aerospace grinders:

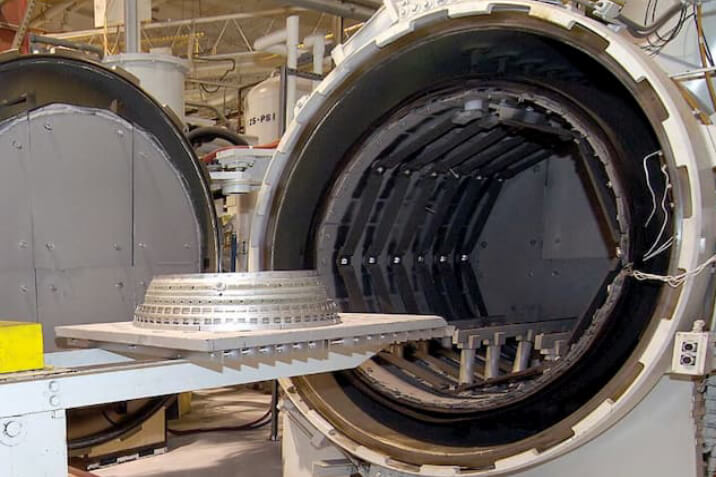

- Precision Grinding:

- Aerospace grinders are designed for precision grinding, allowing for the accurate shaping and finishing of various aerospace components. Precision is crucial in the aerospace industry to meet the stringent requirements for safety and performance.

- Material Removal and Surface Finishing:

- Aerospace grinders are used to remove material from components, ensuring that parts meet exact specifications. Additionally, these grinders are capable of providing a high-quality surface finish, which is essential for components that require smooth and precise surfaces.

- Types of Aerospace Grinders:

- Various types of grinders may be used in aerospace applications, including surface grinders, cylindrical grinders, and tool and cutter grinders. Each type is chosen based on the specific requirements of the aerospace component being processed.

- CNC (Computer Numerical Control) Technology:

- Many modern aerospace grinders are equipped with CNC technology, allowing for automated and computer-controlled precision grinding. CNC capabilities enhance accuracy, repeatability, and the ability to produce complex shapes.

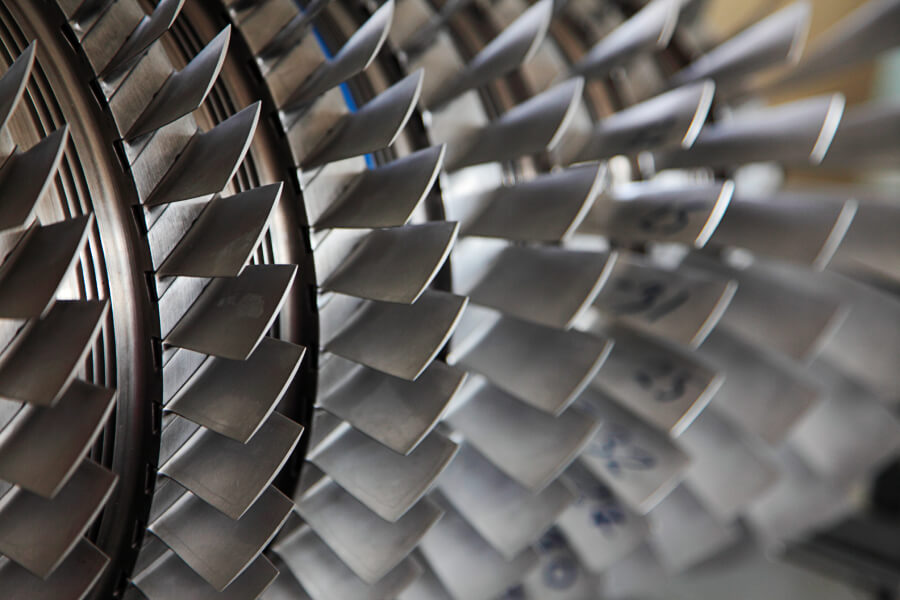

- Grinding of Critical Components:

- Aerospace grinders are used for grinding critical components such as turbine blades, engine components, landing gear parts, and other high-precision elements. These components often require tight tolerances and superior surface finishes for optimal performance.

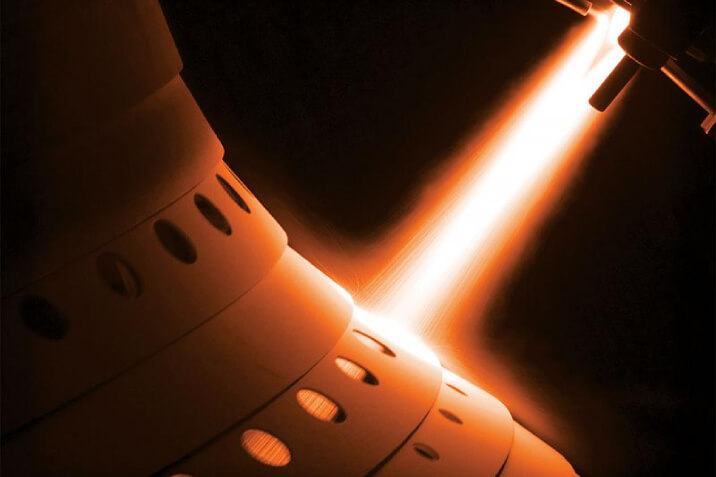

- Coolant Systems:

- Aerospace grinding processes generate heat, and to prevent thermal damage to the workpiece and maintain accuracy, aerospace grinders often incorporate effective coolant systems. These systems help in maintaining stable temperatures during the grinding process.

- Tooling and Abrasives:

- Aerospace grinders use specialized tooling and abrasives suited for the materials being processed. The choice of abrasives and grinding wheels is critical to achieving the desired results without compromising the integrity of the aerospace components.

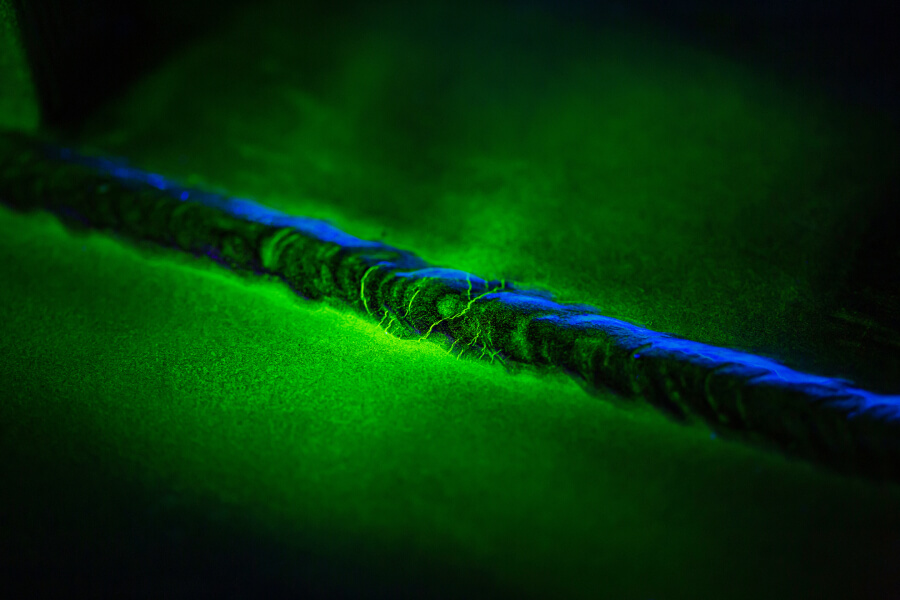

- Quality Control and Inspection:

- Aerospace grinders are often integrated into comprehensive quality control systems. After grinding, components are inspected using various non-destructive testing (NDT) methods to ensure they meet the required standards and specifications.

- Safety Features:

- Given the precision and high-speed operation of aerospace grinders, safety features are paramount. These may include protective enclosures, emergency stop mechanisms, and other safety measures to protect operators and prevent accidents.

Aerospace grinders play a vital role in the manufacturing and maintenance of aerospace components, contributing to the overall safety, reliability, and performance of aircraft. They are essential tools in the production of precision-engineered parts for the aerospace industry.