NDT, or Non-Destructive Testing, is a set of techniques used to evaluate the integrity and properties of materials, components, or systems without causing damage. In the aerospace industry, NDT inspection is crucial for ensuring the safety and reliability of aircraft components. Here are some common NDT methods used in aerospace inspections:

- Visual Inspection (VI):

- The simplest form of inspection involves visually examining the aircraft structure, components, or systems. This can be done with the naked eye or with the assistance of tools like borescopes. Visual inspection is often the first step in identifying potential issues.

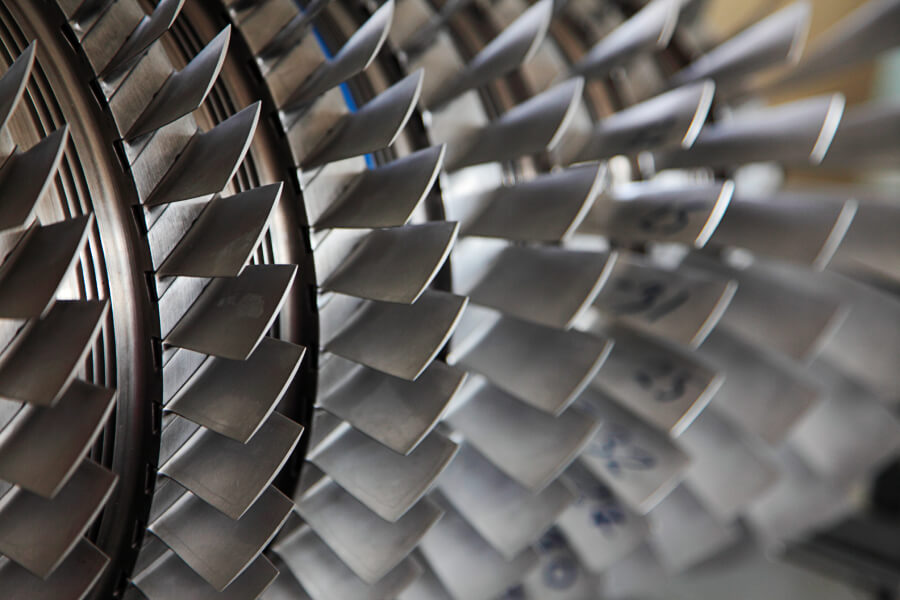

- Ultrasonic Testing (UT):

- Ultrasonic waves are used to detect internal flaws or anomalies in materials. A transducer sends ultrasonic waves into the material, and the reflected waves are analyzed to identify defects such as cracks, voids, or delaminations. UT is commonly used for inspecting welds, engine components, and composite materials.

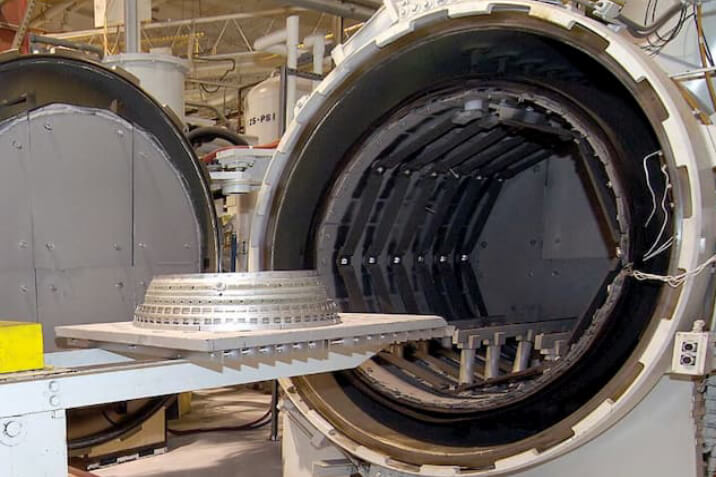

- Radiographic Testing (RT):

- X-rays or gamma rays are used to create images of the internal structure of components. This method is effective for detecting internal defects such as cracks, inclusions, or voids. RT is often used for inspecting aircraft structural components and complex assemblies.

- Eddy Current Testing (ECT):

- Eddy current testing involves inducing electrical currents in a conductive material and monitoring changes in the electromagnetic field. This method is particularly useful for detecting surface cracks, corrosion, and variations in material properties. ECT is commonly used for inspecting aluminum structures.

- Magnetic Particle Testing (MPT):

- MPT is used to identify surface and near-surface defects in ferromagnetic materials. Magnetic particles are applied to the surface, and a magnetic field is applied. The particles accumulate at defect locations, making them visible for inspection. MPT is often used for inspecting critical components like landing gear.

- Liquid Penetrant Testing (LPT):

- LPT involves applying a liquid dye or fluorescent penetrant to the surface of a component. The penetrant seeps into surface-breaking defects, and after a certain dwell time, excess penetrant is removed. A developer is then applied to make the defects visible under UV light. LPT is useful for detecting cracks and other surface defects.

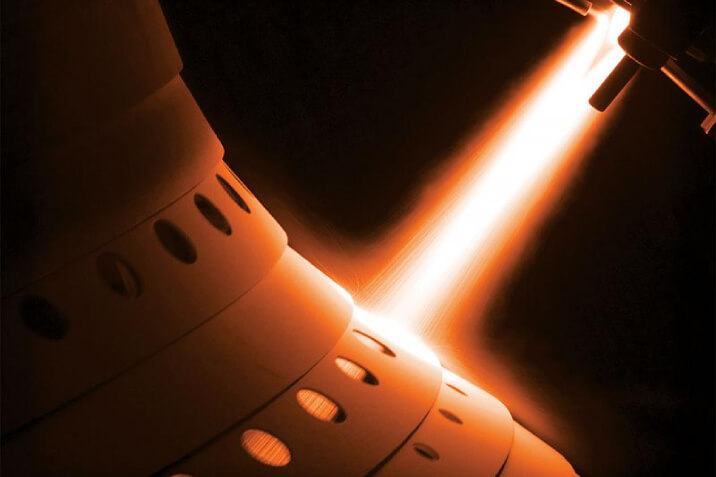

- Thermal/Infrared Testing (IRT):

- IRT utilizes the infrared radiation emitted by an object to identify temperature variations. This method is often used to detect abnormalities in composite materials, electrical systems, or other components that may exhibit thermal anomalies due to internal defects or malfunctions.

- Acoustic Emission Testing (AET):

- AET involves monitoring the release of acoustic signals or waves from a material or structure under stress. This method can detect the initiation and propagation of defects, such as cracks, and is used for continuous monitoring of critical components.

NDT plays a vital role in aircraft maintenance and quality control, helping to identify potential issues before they can lead to catastrophic failures. These methods are applied at various stages of an aircraft's life, from manufacturing to regular maintenance inspections.