Shot peening is a metalworking process used in the aerospace industry to enhance the fatigue life and durability of metallic components, particularly those subjected to cyclic loading and stress, such as aircraft parts. The process involves the controlled bombardment of the material's surface with small spherical media, known as shot, usually made of steel or other materials.

Here are the key aspects of aircraft shot peening:

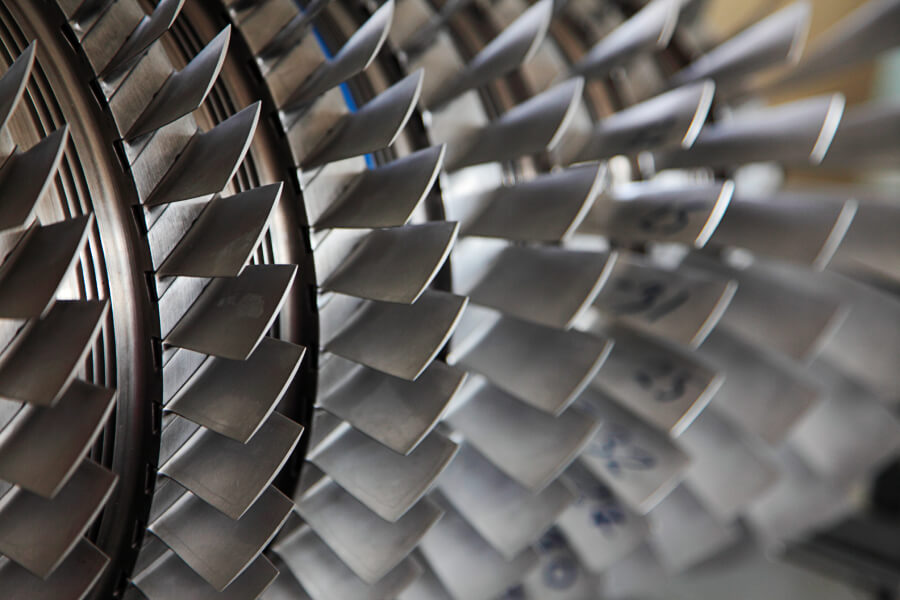

- Purpose:

- Shot peening induces compressive stresses into the surface layer of a material, which improves its resistance to fatigue and stress corrosion cracking. This is particularly critical for components like aircraft engine turbine blades, landing gear, and other structural elements.

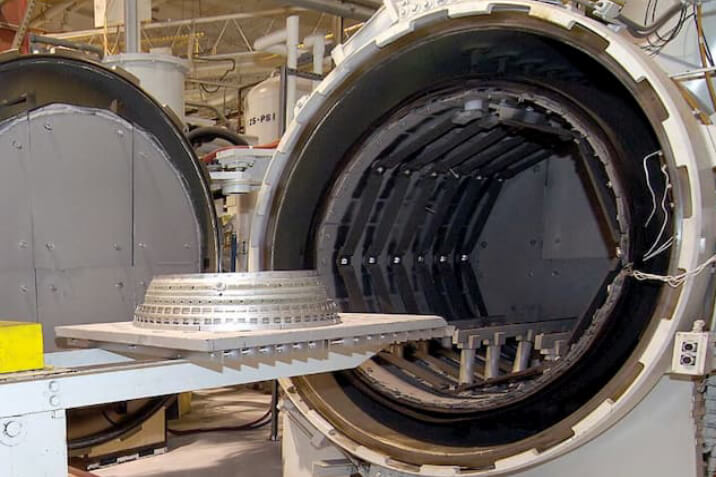

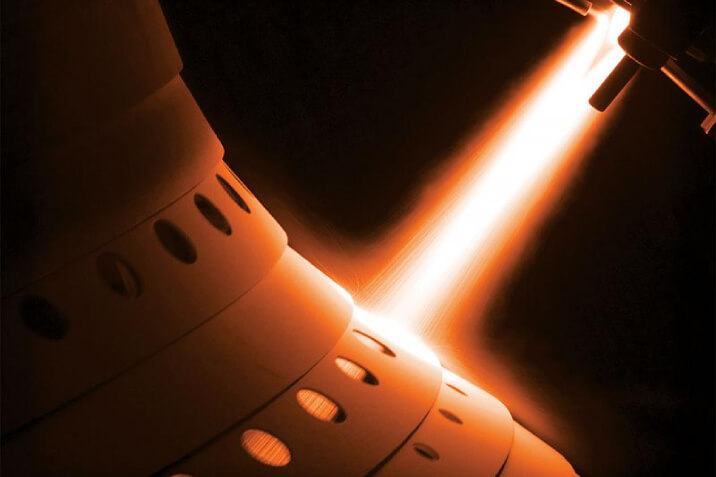

- Process:

- The shot peening process typically involves the use of air-driven or wheel-based peening equipment. The shot media is accelerated and directed at the surface of the component, creating controlled plastic deformation. This induces beneficial compressive stresses in the material.

- Media:

- The choice of shot media depends on the material being treated and the desired outcome. Steel shot is common, but other materials like glass beads, ceramic shot, or even specialized materials may be used for specific applications.

- Controlled Parameters:

- Shot peening requires precise control of various parameters, including shot size, velocity, coverage, and the duration of the peening process. These factors influence the depth and intensity of the induced compressive stresses.

- Coverage:

- It's essential to ensure complete coverage of the component's surface during shot peening to achieve uniform compressive stress distribution. This is typically specified based on industry standards and the requirements of the specific component.

- Benefits:

- Shot peening provides several benefits, including increased resistance to fatigue, improved durability, and enhanced performance under cyclic loading conditions. It helps extend the lifespan of critical aircraft components, contributing to overall safety and reliability.

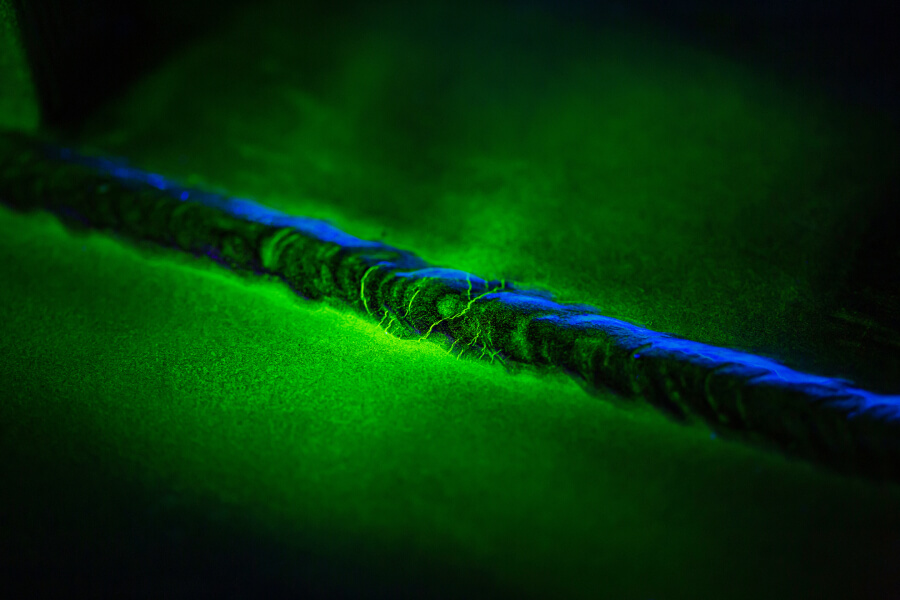

- Post-Peening Inspection:

- After shot peening, components undergo thorough inspection to verify the effectiveness of the process and ensure that specifications are met. Non-destructive testing methods, such as ultrasonic testing, may be used to assess the induced compressive stresses.

- Regulatory Compliance:

- Aerospace shot peening processes must comply with industry standards and regulatory requirements. These standards ensure that the treatment meets the necessary safety and quality standards set by aviation authorities.

Aircraft shot peening is a critical part of the aerospace manufacturing and maintenance processes, contributing to the overall safety and longevity of aircraft components subjected to high levels of stress during operation.